Killed steel is steel that has been treated with a strong deoxidizing agent typically silicon manganese and aluminum but also sometimes vanadium titanium and zirconium.

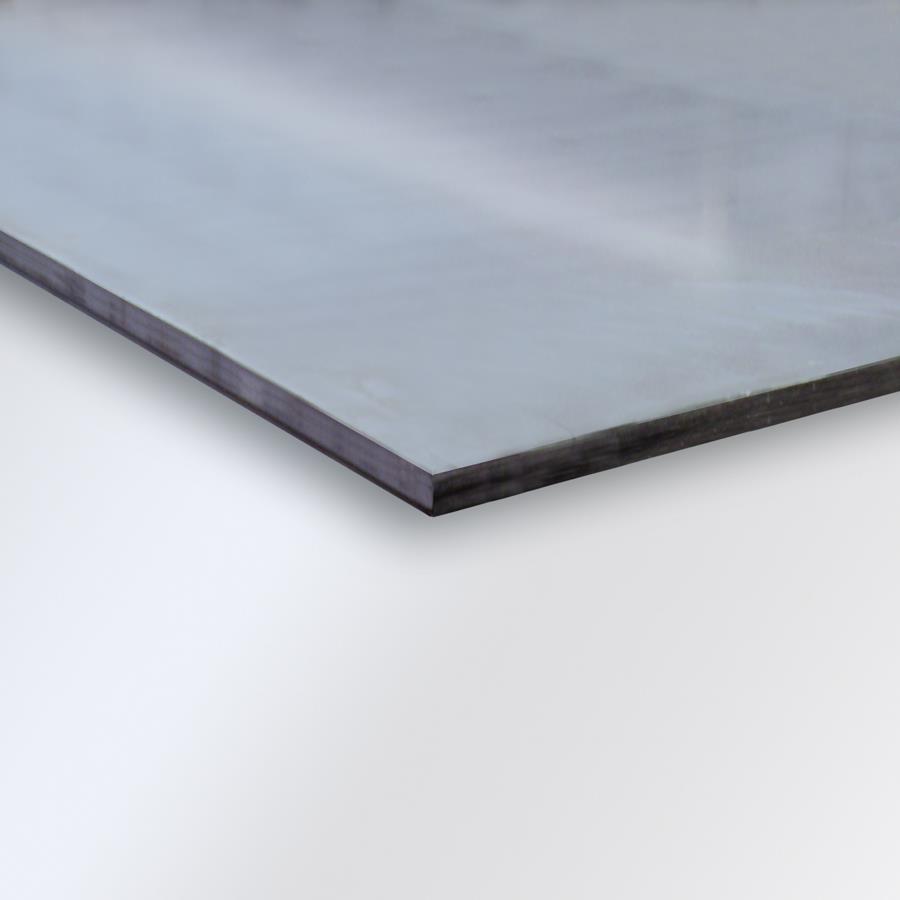

Aluminum killed sheet metal.

In stock and ready to ship.

Akdq is aluminum killed draw quality correct guage and has the formability desired for making parts.

Aluminum killed akdq steel sheet is produced especially for fabricating into parts requiring severe forming or drawing operations too difficult for the drawing properties of commercial quality cold roll steel.

The benefit of the aluminum killed process is uniformity and consistent performance because the addition of aluminum locks up the oxygen that normally occurs in the form of aluminum oxide.

Answers to your specific questions are as follows.

Akdq stands for aluminum killed drawing quality.

The end result is an a1008 steel sheet that can be oxy acetylene or tig welded with no gas bubbles forming.

Industrial metal supply stocks a full line of aluminum sheet and plate.

Addition of aluminum also refines the prior austenite grain size.

Schmitt and jalinier measured the material density using an electronic thermocontrolled balance and an electron microscope and modeled the growth of voids.

What gauge metal to use.

We offer a variety of alloys including a large inventory of 6061 in a range of standard sizes and thicknesses.

It is commonly used in the transportation food and aerospace industry due to its light weight and resistance to corrosion.

It is measured by its thickness gauge.

I have to buy 3 sheet minimum at 2 5x a regular sheet just to get it here.

The benefit of the aluminum killed process is uniformity and consistent performance because the addition of aluminum locks up the oxygen that normally occurs in the form of aluminum oxide.

Aluminum flat sheet is a thin flat piece of aluminum with many applications.

This treatment reduces the oxygen content so that during solidification.

To the naked eyes of many end users of the popular metal however steel is likely just steel.

We can provide custom cut to size aluminum sheet metal to meet your exact requirements.

It refers to the adding aluminum to molten steel during the alloy process followed by the annealing and tempering the sheet undergoes.

When voids nucleated due to the separation of the inclusions from the matrix the change in the material density in uniaxial tension was smaller than the change.

Schmitt and jalinier 1982 performed the uniaxial tension and the balanced biaxial tension of a sheet using aluminum killed steel electrolytic copper and 3003 aluminum alloy.

Choose from our selection of aluminum sheet metal in a wide range of styles and sizes.